The choice of materials when building prototypes depends largely on the type of prototype, the stage of development, the functional requirements and the available budget. Here are some common materials used in various phases of prototyping:

Early stages (low-fidelity prototypes)

Paper and Cardboard : Ideal for very early, simple models to visualize the design concept.

Foam and Styrofoam : Good for slightly more detailed, but still inexpensive and quick modelling.

Wood : For slightly more robust models that allow for some processing, but are still relatively simple and inexpensive.

Plasticine or modeling clay : Allows quick shape changes and is ideal for ergonomic studies.

Later stages (high-fidelity prototypes)

Plastics (such as ABS, PLA, PETG) : Widely used in 3D printing technology and for detailed, functional prototypes that are close to the final product.

- Metals (such as aluminum or steel) : For parts requiring high strength or thermal conductivity, often used in mechanical components or for end-user testing.

- Silicone and Rubber : For flexible parts or components intended to provide seals or grips.

- Resins : Used in stereolithography (SLA) or digital light processing (DLP) for prototypes with very high levels of detail.

Specialized materials

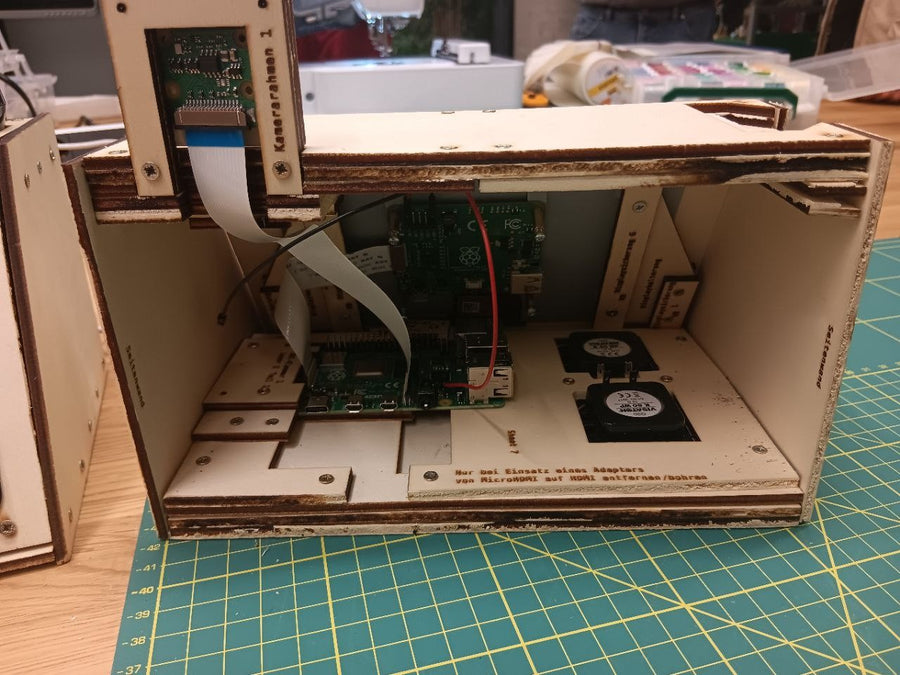

- Electronic components : For prototypes that contain electronic functions, including LEDs, microcontrollers (such as Arduino or Raspberry Pi), sensors, and circuits.

Glass or Ceramic : Specific to industries where these materials are key, although less common in general prototyping.

- Composites and Composites : For special applications that require a combination of lightness and high strength, such as in aerospace or automotive manufacturing.

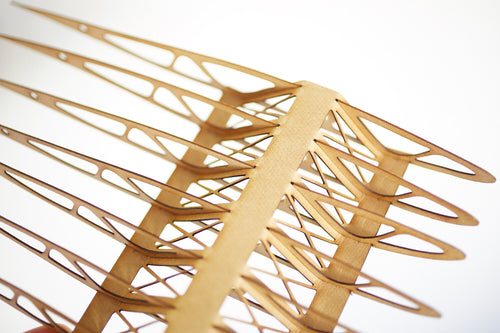

Deciding on specific materials should also take into account the methods used to make the prototype, such as CNC milling, laser cutting, 3D printing or handcrafting, as not all materials are suitable for every technique. It is also important to think about the entire life cycle of the prototype, including aspects such as durability, cost, availability and environmental impact. The Mr Beam can definitely support you in both phases of prototype construction, depending on the material. You are also welcome to send us materials for testing. Simply contact our sales team.

![Mr Beam dreamcut [x] Lasercutter](http://www.mr-beam.org/cdn/shop/files/mr-beam-dreamcut-x-laser-hero.jpg?v=1704362921&width=2400)