Stefan introduces himself

Hello Stefan, please introduce yourself briefly. Who are you and what are you doing?

I am Stefan Baur, born in 1977, a trained IT specialist in systems integration, and I have been the boss of my own small IT company here in Ulm since the end of 2009. We have been a pure service company with a focus on open source for a good 10 years . In much the same way that Mr Beam relies on the open source software OctoPrint and offers its own extensions and support, we offer support for X2Go , an open source remote desktop and remote application solution. But, unlike Mr Beam, we don't sell any hardware. 😉

A project with heart 🧡

You currently have a special project. Introduce us to the Grannophone. How did the idea come about?

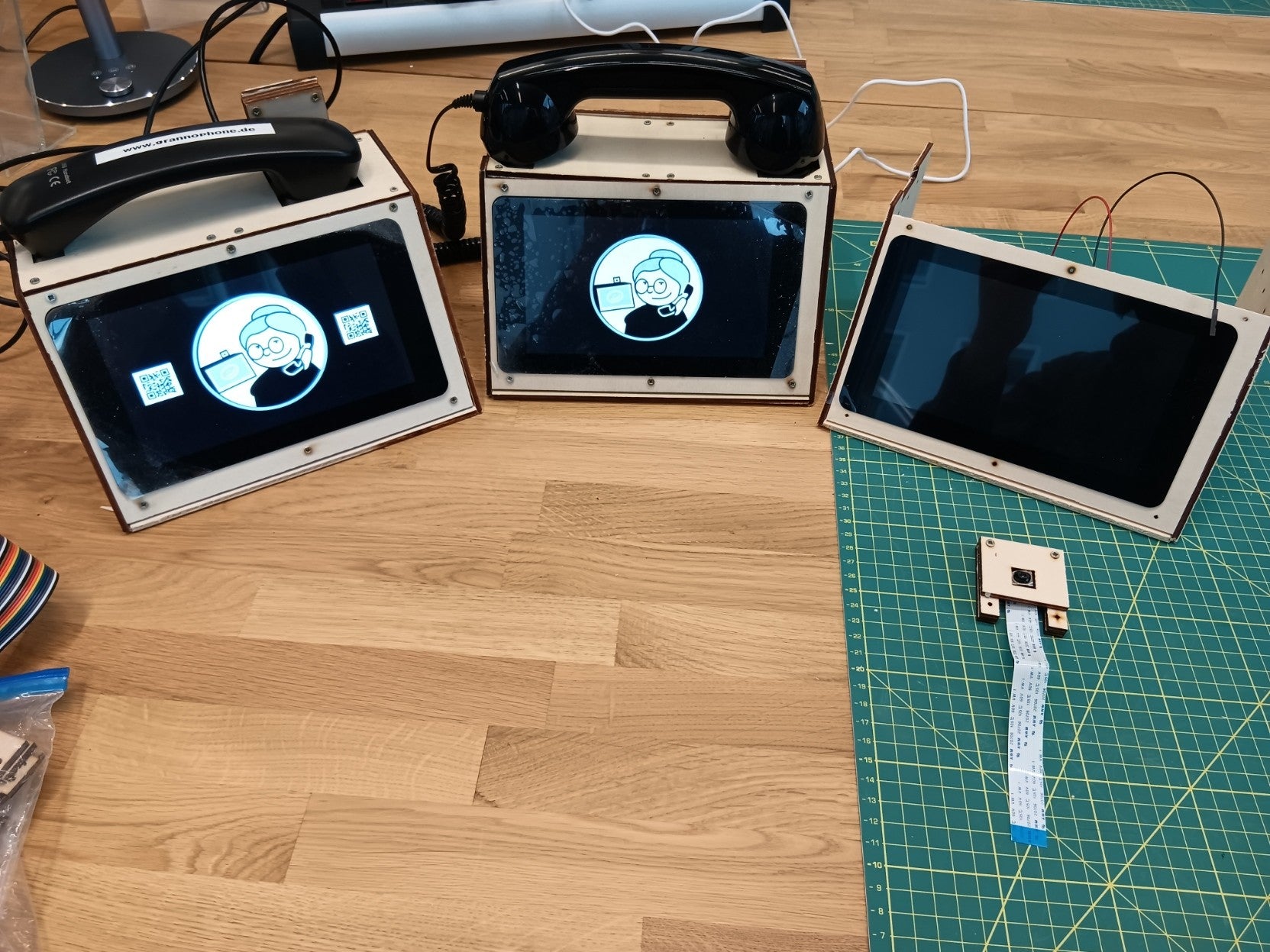

The Grannophone is a video phone currently in development for seniors and dementia patients. The idea is that you can assemble it at your kitchen table at home with minimal use of tools and without much prior knowledge from components that are as standardized as possible and, above all, without soldering, using only plug-in, clamping and screw connections. So to speak, “kit furniture meets model railway”.

The idea came about in November 2020, during the 2nd Corona lockdown aka “Lockdown light”. Someone I follow on Twitter publicly asked how he could get his grandma, who has a big TV and good internet but no knowledge of technology, to be able to make video calls with him.

At that time I had to answer him that he could forget about the TV and better give his grandma a large, older tablet from this company, whose most prominent executive was a guy with wire-rimmed glasses, a black turtleneck, blue jeans and white sneakers who gave his product presentations usually like Inspector Columbo ended with a "just one more thing".

Inventiveness develops out of frustration

And that frustrated me so much that I said to myself, it has to be done differently , it has to be easier, it has to be cheaper and more sustainable - and so I got to work. Open source is of course the method of choice when it comes to the software side - it doesn't get cheaper than "free".

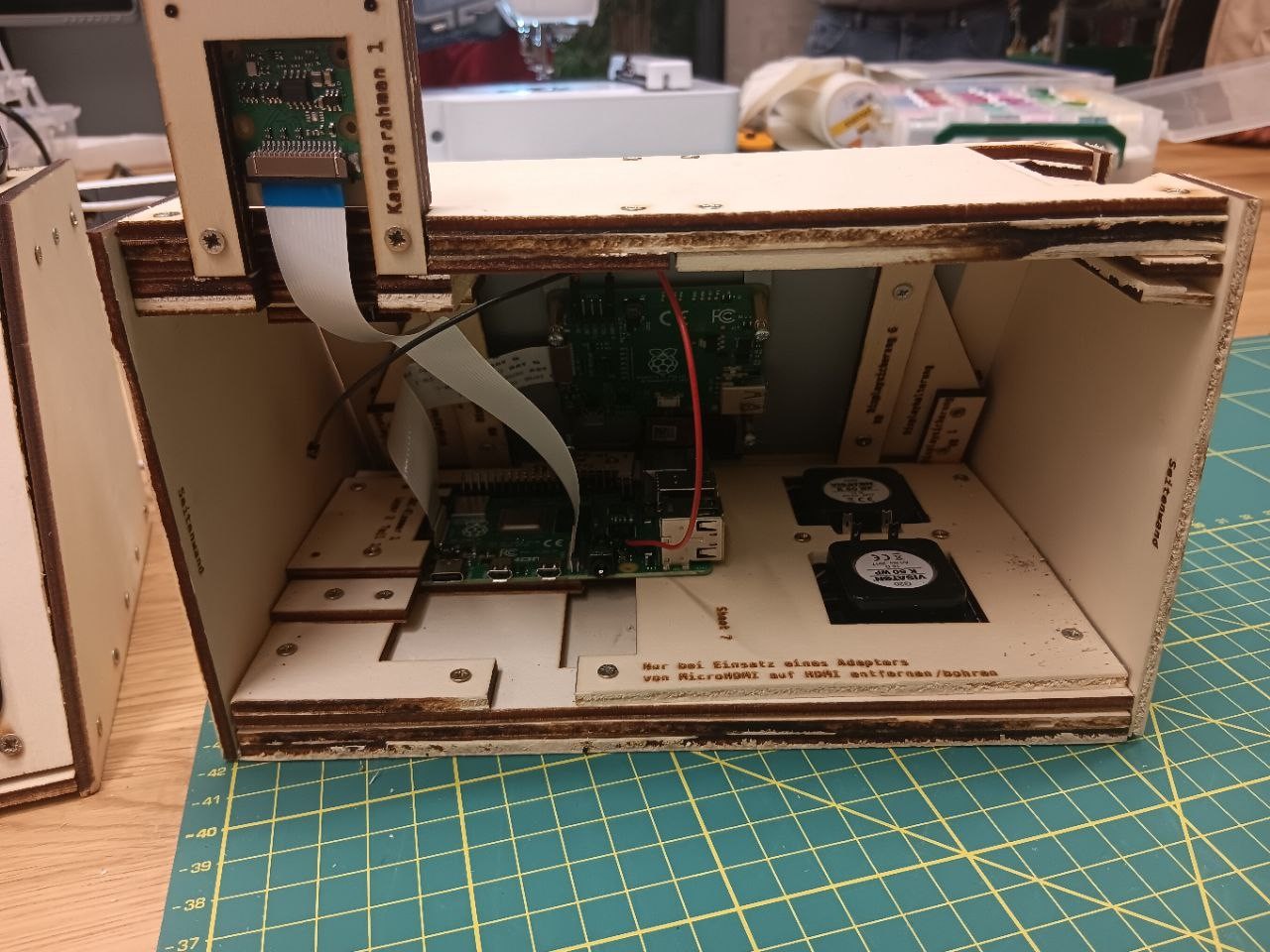

The electronics interior consists of a Raspberry Pi 4 with the 7-inch display and the PiCam 2 or PiCam 3, which you can get as official accessories, a few microswitches from the electronics store, and a USB handset. All that's missing is a housing around it - and plywood is cheap and you can work on it without any special tools, just with a hand drill, fret saw and file. With MDF or acrylic glass, doing it by hand would be much more demanding.

What problems did you face during implementation?

Well, the first prototypes were created with a jigsaw at the kitchen table at home. In other words, exactly as it should be done later by family members who want to build a Grannophone for their parents/grandparents .

Only: If something doesn't fit during manual prototyping, you're always left wondering whether it's because you made a mistake in the plan or because you saw and/or measured too imprecisely...

The Mr Beam comes into play to help

How does Mr Beam support you in the project?

... and this is exactly where the strength of Mr Beam comes into play. The tolerances in laser cutting are negligibly small. So if the lasered parts don't fit together, the error must most likely be in the plan. Okay, occasionally it happens that it's due to warped wood . Although I have to admit that I usually buy these at the hardware store and don't order them from Mr Beam, and the hardware store quality has fluctuated more than I would like lately. But using “good” Mr Beam wood for prototyping always seems like a waste to me.

Makerspaces as an alternative to your own Mr Beam

How did you find out about Mr Beam? Through the Makerspace in Ulm or before?

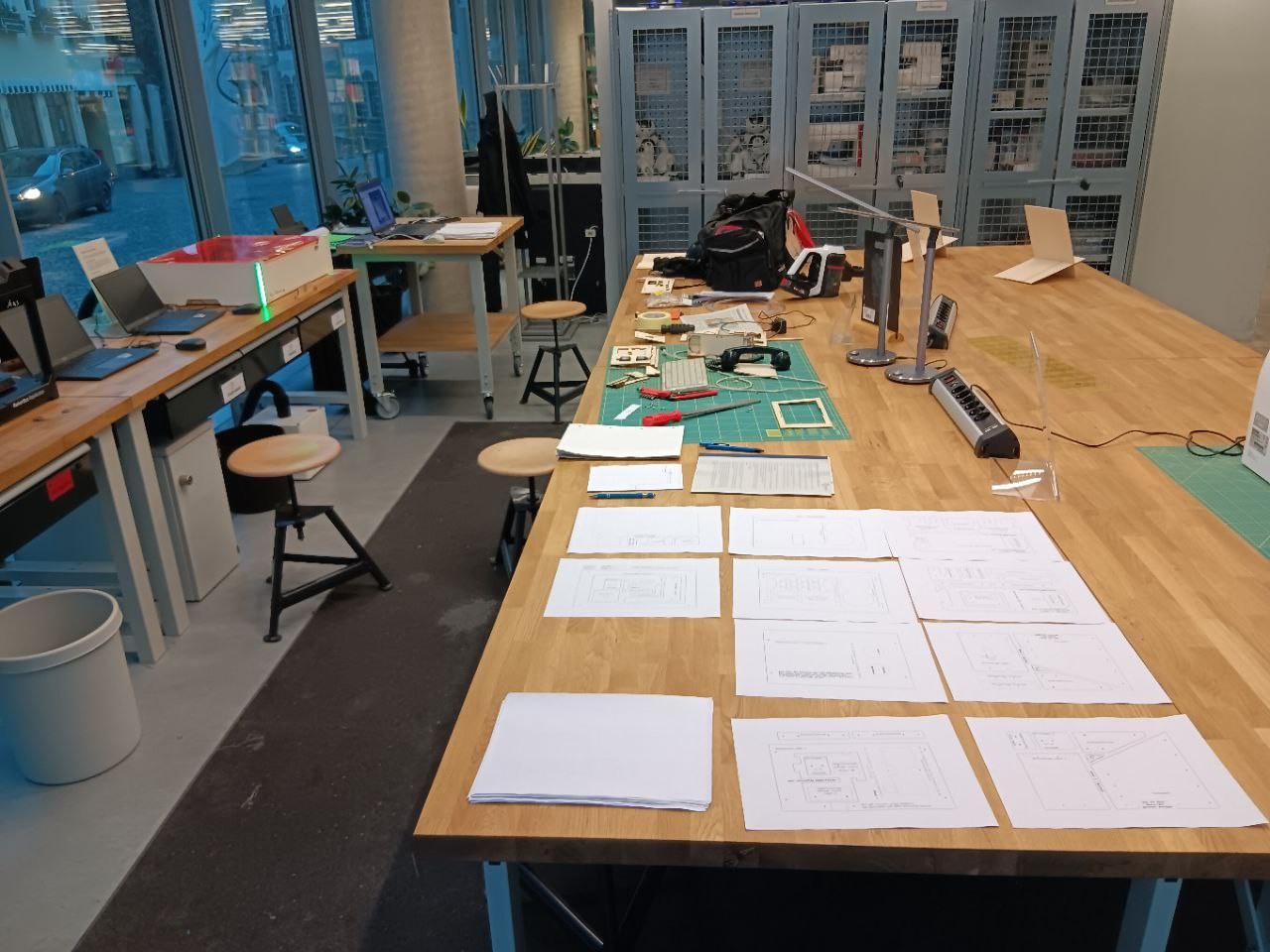

I can actually only answer the question by taking a step back: How did I become aware of the Makerspace? And our former mayor of Ulm, Gunter Czisch, is to blame for that. He was voted out in December 2023, but at the beginning of 2023 he was still in office - and had a public mud fight over usage and naming rights with a non-profit association that used urban spaces for a hacker space. This not only made it into his Wikipedia article, but also into the local newspaper.

In this article, representatives of the association, which has now been renamed Temporärhaus eV for legal reasons, were also mentioned, and they mentioned that, despite similar equipment, they did not see the makerspace in the city library as competition, but rather as a complement. Then I pricked up my ears, took a look at what was on offer in the Makerspace, and a month later I was officially instructed in how to use it.

Step by step

What projects are planned for the future?

If tinkering of a general nature is meant, I have been planning something on the subject of solar cell upcycling and AI-supported recording of hotline telephone calls (utility model registered) for a long time.

As far as laser cutting is concerned, I want to finish the Grannophone first - starting too many projects only means that nothing gets finished in a timely manner. There may be smaller things in between, like a kind of "cable comb" through which you can thread the cables of the peripheral devices in the makerspace and then lock them so that they are protected from theft and you don't always have to dismantle them in the evening.

Can you imagine continuing to use Mr Beam in the future?

If projects arise where you can do useful things with a laser machine, certainly. It may also result in me passing on my knowledge to others who want to implement projects with the laser cutter in the Makerspace - because its motto is "From idea to project".

For me, after the Grannophone or for some small stuff on the side, I'll probably go more towards additive rather than subtractive processes, i.e. 3D printers. If you're in the makerspace anyway and work with Mr Beam, he can 3D printers also do something on the side instead of just sitting there unused. Last summer I replicated parts of a garden lounger, and in the winter before that I replicated control knobs for a night storage heater, for which the manufacturer no longer has spare parts .

Feedback promotes progress

Do you have any suggestions or requests for improvements to the Mr Beam?

You're talking about something. The software still sometimes has its own peculiarities. Somehow, at least “our” Mr Beam occasionally gets out of step with which message he should display. Especially if he has to take frequent cool-down breaks, the "hourglass" pop-up occasionally no longer appears, but the one that should actually only appear if you have manually pressed the pause button.

Sometimes it also chokes on uploaded SVGs , so only restarting the browser - or even the entire Mr Beam - helps. It would be nice to be able to look "under the hood" (no, not under the laser protection hood 😉) to see what's happening; So whether, for example, the main memory has run out or the SD card has filled up or something like that. Any way in which an advanced user could at least access the system to read or have any status or error messages displayed would be helpful.

However, that is not necessary at all. The Ulm City Library should go to our download area and install the stick to delete the design files. Then the Mr Beam runs like new again. 😇

Regarding your shop, as already indicated above, I would like to suggest that you could perhaps also offer 4mm poplar plywood in both better and worse quality levels than just "AB/B", of course at different prices. For prototyping, "BB" or "C" usually works, but for a nice outside you might also want to use "A".

Support is important!

How can we support you with your project?

Well, there are several options:

If the journey to Ulm isn't too far for you, you're welcome to come to my laser cutting appointments in the makerspace and tinker with me, brainstorm, etc.

There is also a media workshop there, whose equipment can be used after instruction. So if you're more visually inclined than technically gifted , you might be able to use it to take some better pictures for the wiki and social media than I can with my cell phone. At the moment the Grannophone has, in addition to its mailing list and its YouTube playlist , both a Twitter / A volunteer social media manager would be a great help. And of course I'm also happy about financial support - around 1,500 euros have now been received through crowdfunding. You can also read how I use the money in the Wiki .

But every retweet/reskeet and like also helps - clicks are the currency of the Internet.

Note on the Grannophone

Finally, I have to say something. The Grannophone is not a project of my company, but a purely private hobby that is not intended to make any profit - it is simply an attempt to make the world a little better. The plans and all the files you might need (including different bell sounds) are available for everyone to download for free on Github . Only those who want to market my reference housing as a kit or finished device, for example, need a license from me. That's why the housing is protected by a utility model (DE: 20 2021 001 690.2), but at the same time released for non-commercial replicas under creativecommons . And if any hackerspace or non-profit association wants to make the things for visitors on an open day or something like that and asks for donations in return - they should just get in touch in advance, then they'll get a letter from me saying that's fine and you don't have to pay any license fees.

Thank you, Stefan! We wish you lots of fun and success in your future tinkering. The insight was very interesting for us. If you want to support Stefan, we have linked all the important links for you above.