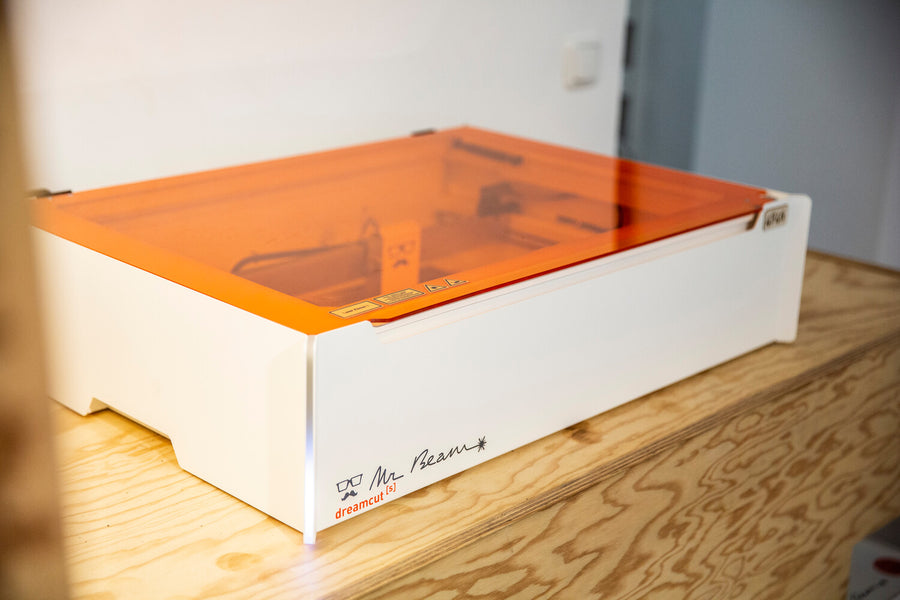

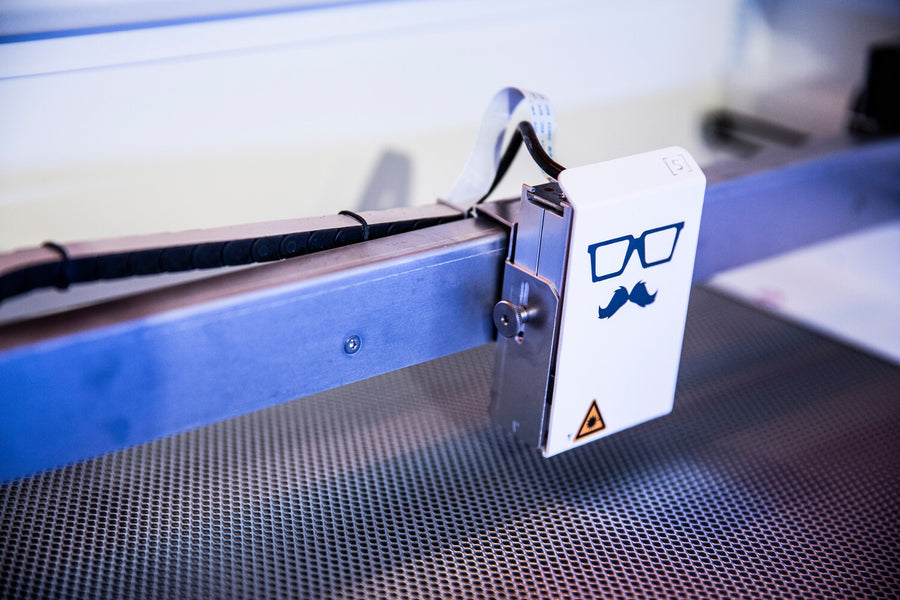

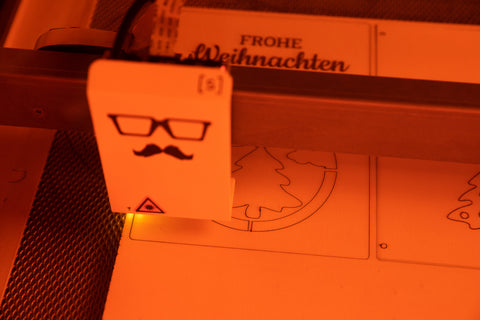

The design of Mr Beam is reminiscent of printers, scanners or 3D printing devices. This is no coincidence, because the functions of these devices are similar. First you need a carrier. While you insert a sheet of paper with a printer, with our laser cutter and engraver, for example, it is a thin wooden board. In the associated graphic file, you store which areas the tailor should cut out. Tutorials and the help area make controlling the software very easy and can be learned in just a few minutes, even without prior knowledge.

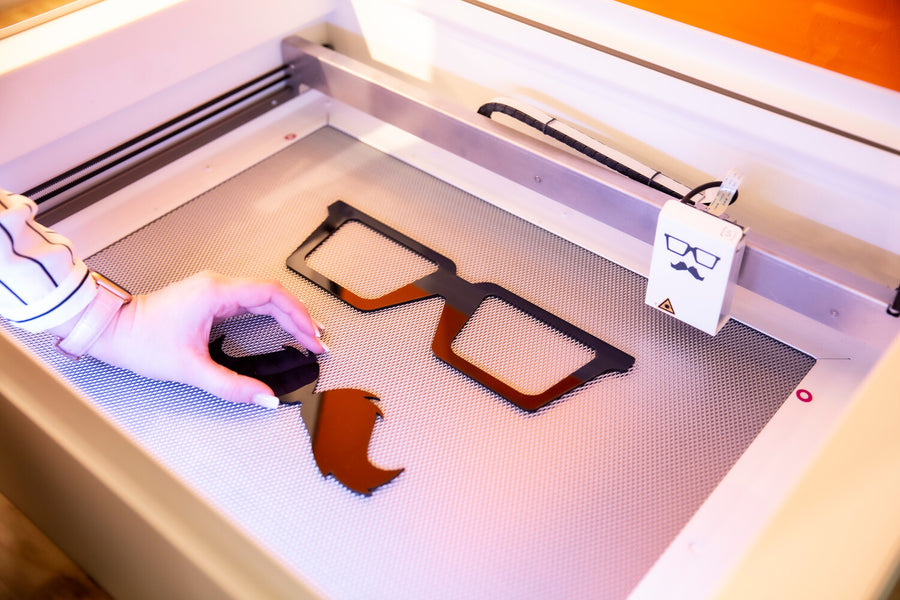

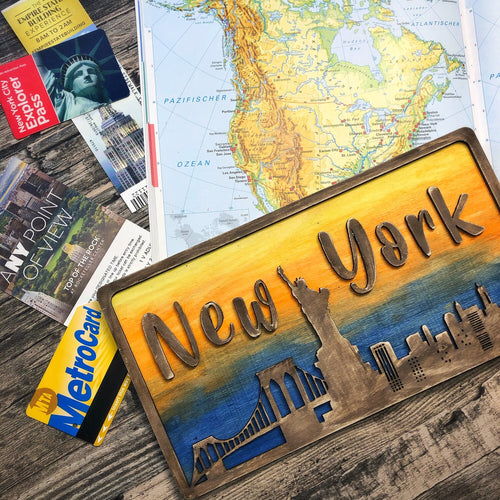

The laser bundles a beam of light that heats up the substrate due to its intensity. Materials behave differently under a laser beam. Wood burns, plastic melts, but in the end there is always a precisely cut line that you can debut later if necessary, so that no sharp edges remain. After the cutting process, you can simply remove the cut part from the blank and process it further, for example painting or assembling it with other components.

![Mr Beam dreamcut [x] Lasercutter](http://www.mr-beam.org/cdn/shop/files/mr-beam-dreamcut-x-laser-hero.jpg?v=1704362921&width=2400)